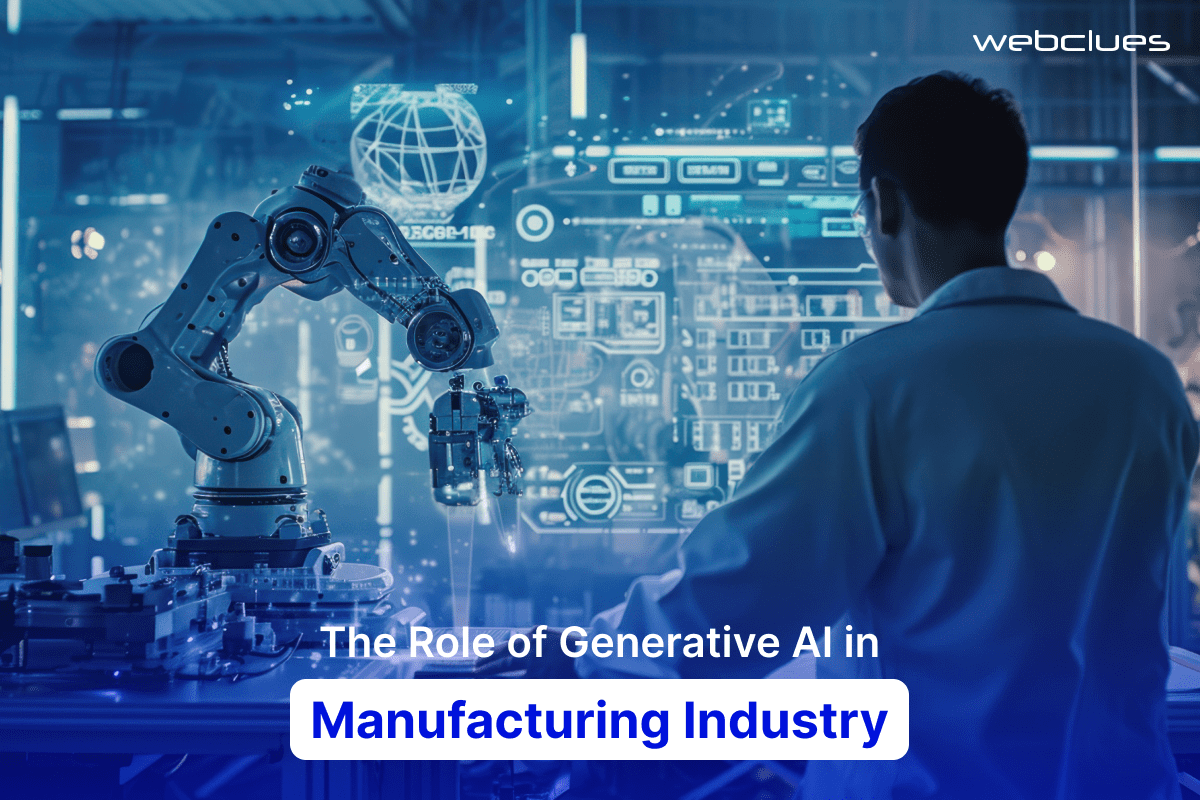

Generative AI in the Manufacturing Industry

The manufacturing industry is a cornerstone of global economies. Akin to many other industries, the continuous integration of advanced technologies like artificial intelligence (AI) is ushering it into a new era altogether. While traditional AI excels at analyzing and learning from existing data, generative AI takes a critical step further, possessing the remarkable ability to create entirely new data. This translates to a revolutionary potential in manufacturing, driving the exploration of innovative design possibilities and optimizing various aspects of production.

According to a recent PWC report, 82% of manufacturers believe AI will play a significant role in their future success. This sentiment is echoed by a McKinsey study, which estimates that AI could contribute up to $2.7 trillion to the global manufacturing sector by 2030. As manufacturers strive for increased efficiency, cost optimization, and product innovation, generative AI development services allows them to generate new designs, materials, and even manufacturing processes.

In this article, we’ll explore the various ways generative AI is revolutionizing different aspects of the manufacturing industry – from design and development to production and supply chain management. We’ll also shed light on the ongoing advancements in generative AI research and its potential to reshape the future of manufacturing.

Transforming Design and Development

Utilizing this pathbreaking technology, a generative AI development company can transform how manufacturers approach product design and development. One of its most impactful applications is generative design.

Generative Design

Generative AI automates the exploration of countless design variations based on predefined parameters and constraints. When fed with desired functionalities, material limitations, and weight restrictions, the AI system generates an array of potential designs, each optimized for specific criteria. This allows engineers to explore innovative possibilities and identify the most efficient and cost-effective solutions, significantly accelerating the design process.

A prime example of generative design in action is Airbus, a leading aircraft manufacturer. They employed generative design to optimize the partition walls in their aircraft, resulting in a remarkable 45% weight reduction while maintaining structural integrity. This breakthrough resulted in significant fuel savings and improved aircraft performance, showcasing how substantially generative can influence design optimization.

Material Simulation

Beyond design, generative AI plays a crucial role in material simulation. Traditionally, manufacturers rely on physical prototypes and extensive testing to understand material behavior under various conditions. However, generative AI can analyze vast datasets and simulate how a material will perform under different pressures, temperatures, and stresses. This virtual testing allows manufacturers to optimize material selection, predict potential issues, and significantly reduce development time and cost.

Predictive Maintenance

Generative AI also paves the way for predictive maintenance, reinventing the way manufacturers manage their production equipment. By analyzing sensor data from machines, AI algorithms can learn from historical trends and predict potential equipment failures before they occur. This proactive approach allows manufacturers to schedule maintenance interventions at optimal times, minimizing downtime, maximizing production efficiency, and extending equipment lifespan. Predictive maintenance leads to substantial cost savings and a more reliable production process.

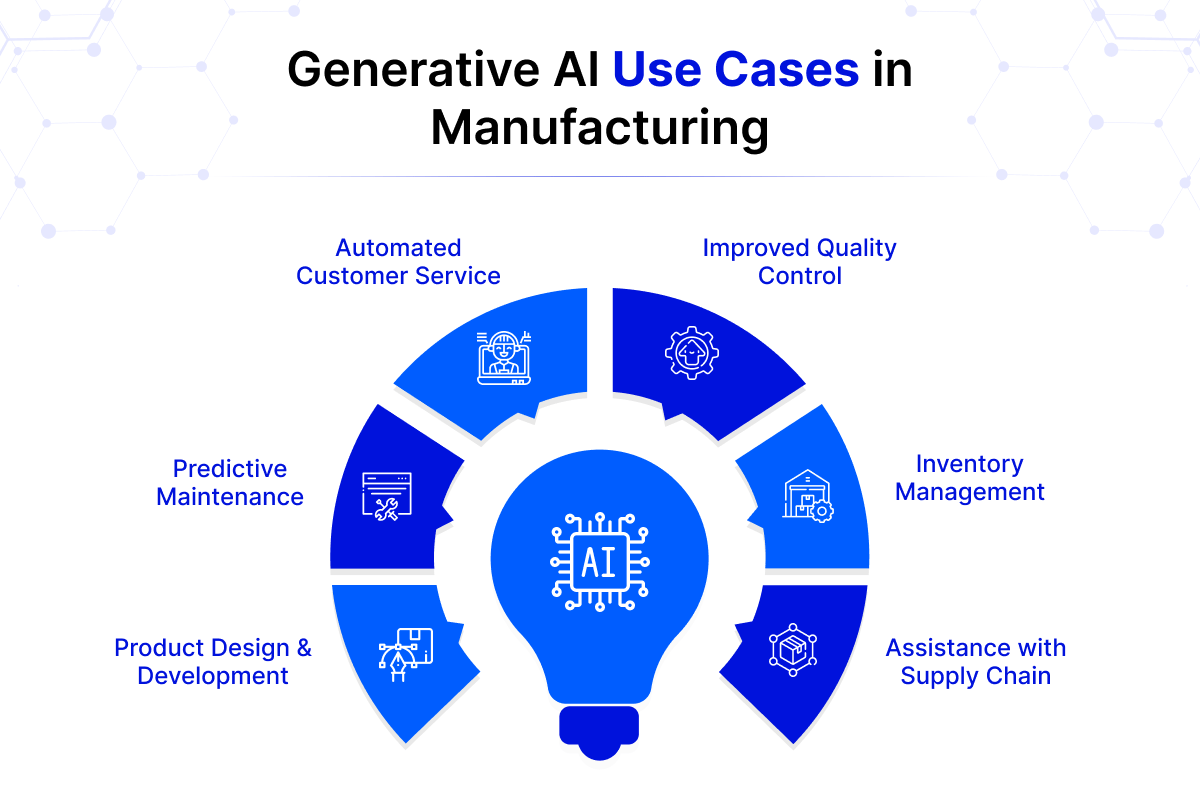

Optimizing Production and Supply Chain

Apart from design and development, generative AI is making significant strides in optimizing production and supply chain management. One exciting application lies in Quality control and Inspection.

Quality Control and Inspection

Generative AI algorithms can be trained on massive datasets of defect-free products to identify anomalies and potential quality issues with exceptional accuracy. This eliminates the need for manual inspections, which are prone to human error and fatigue, resulting in improved product quality and consistency. Additionally, AI-powered inspection systems operate at significantly higher speeds, boosting production efficiency and throughput.

Generative AI not only automates visual inspection but also helps manufacturers improve the quality and efficiency of their inspection processes, as it can generate synthetic data that can be utilized to train quality control systems. This is particularly beneficial in two scenarios:

- Rare or Complex Situations: Real-world data for specific defects or scenarios might be scarce, limiting the effectiveness of traditional training methods. However, generative AI can create realistic and diverse synthetic data simulating specific scenarios, even those rarely encountered in production. This allows for the development of robust and efficient quality control models that can identify defects with higher accuracy across a wider range of situations.

- Improved training efficiency: Compared to traditional data collection methods, generative AI can produce large volumes of synthetic data much faster and at a lower cost. This translates to faster training times for quality control systems, improving adaptability to new situations, along with their performance over time.

Furthermore, generative AI is increasingly being used in conjunction with augmented reality (AR) for quality control applications. AR overlays can be used to visualize potential issues identified by AI systems. This helps technicians remotely inspect and troubleshoot problems. Moreover, this innovative approach allows for faster and more efficient problem-solving, reducing downtime and improving overall production efficiency.

By leveraging generative AI and AR together, manufacturers can create a powerful and effective quality control ecosystem, leading to consistent product quality and minimizing production delays.

Optimized Supply Chain

Moving beyond the factory floor, generative AI lets manufacturers optimize their supply chains. By analyzing historical sales data, market trends, and external factors, AI models can predict future demand with remarkable accuracy. This allows manufacturers to optimize inventory management and thus ensure they have the right materials at the right time to meet customer needs. Furthermore, AI can analyze logistics and transportation data. This helps in identifying routes and strategies to reduce costs and improve delivery efficiency. Through this proactive approach, manufacturers can become more responsive to market fluctuations and disruptions, maintaining a competitive edge.

Personalized Manufacturing

The future of manufacturing holds the potential for even greater personalization with the help of generative AI. Consider a scenario where customers can co-create products by specifying their preferences and needs through an AI-powered interface. The AI system can then cater to individual desires by leveraging generative design and material simulation capabilities to create customized product options. This level of personalization can lead to increased customer satisfaction, improved brand loyalty, and even open up new revenue streams through customized product offerings. With continuous advancement in generative AI technology, the possibilities of personalized manufacturing are becoming limitless.

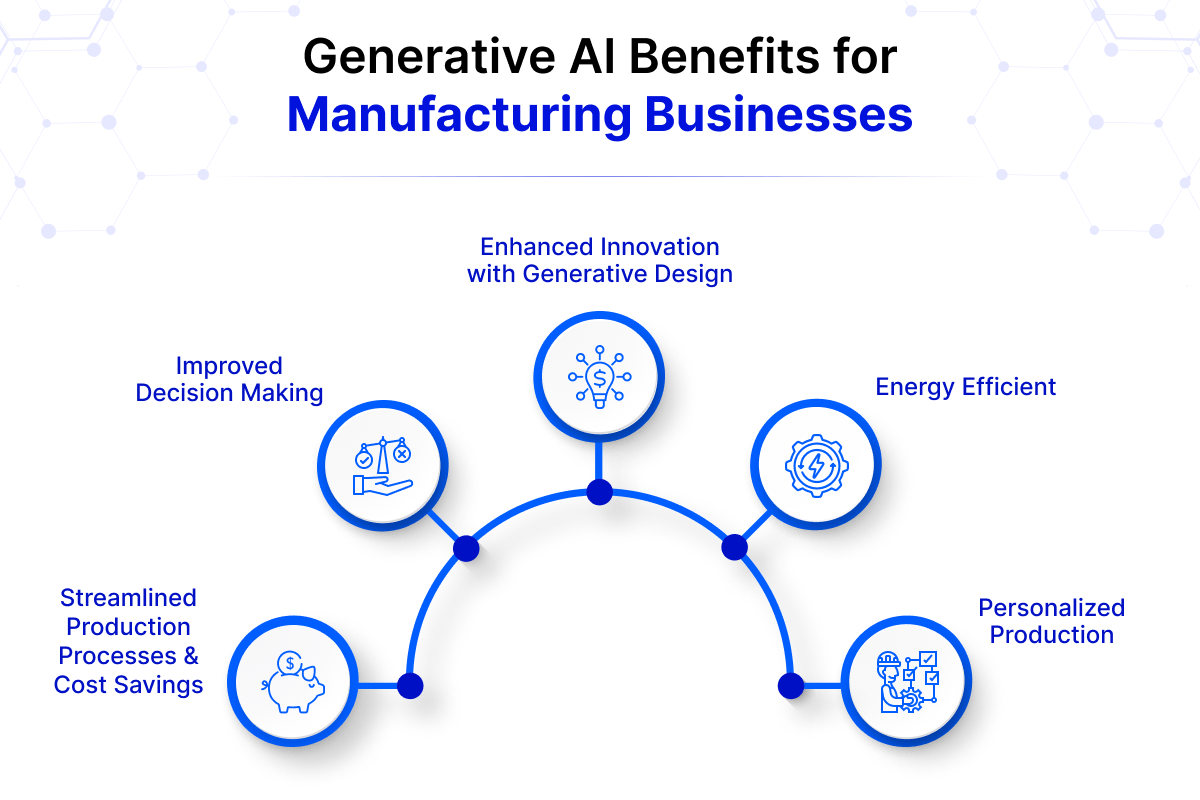

Benefits of Generative AI in Manufacturing

Generative AI offers a range of impactful benefits in manufacturing, driving its rapid adoption.

Improved Efficiency and Productivity

Generative AI optimizes workflows by automating and exploring various design possibilities. This accelerates development cycles and production processes, resulting in increased throughput and overall productivity. Plus, AI algorithms analyze data to identify the most efficient use of materials, energy, and labor, leading to significant resource savings and simplified complex processes.

Cost Reduction and Optimization

Generative AI contributes directly to cost reduction in multiple ways. It helps minimize waste through AI-powered material selection and design optimization, reducing unnecessary material consumption. Moreover, predictive maintenance capabilities facilitate proactive equipment sustenance, minimizing downtime and associated repair costs.

Data-Driven Decision Making

Generative AI provides manufacturers with real-time insights gleaned from vast amounts of data. This provides them with actionable information to optimize production processes, resource allocation, and overall decision-making. Plus, AI can identify potential risks and predict future events based on historical data and market trends. This enhanced risk management allows manufacturers to make informed decisions and proactively mitigate challenges.

Reduced Downtime and Increased Uptime

Downtime minimization is a crucial benefit offered by generative AI. It can help in identifying and addressing bottlenecks in production processes, leading to smoother operations and reduced downtime. Furthermore, enhanced equipment condition monitoring allows for timely intervention and prevents minor issues from escalating into major breakdowns, ultimately maximizing equipment uptime.

Competitive Advantage

Generative AI’s ability to design, test, and iterate on products rapidly allows companies to bring new offerings to market faster than competitors. Moreover, reduced production costs achieved through enhanced efficiency and optimization lead to a competitive edge in terms of pricing and profitability.

Challenges and Considerations

While generative AI presents a compelling vision for the future of manufacturing, its successful implementation requires careful consideration of several challenges:

Data Availability and Quality

Generative AI models, like any AI system, require vast amounts of high-quality data to learn and produce reliable results. However, manufacturers might face challenges in acquiring sufficient data for effective training due to several factors. For instance, limited historical data, particularly for smaller players can hinder the model's ability to learn effectively and generalize to new situations. Also, confidential data around processes, materials, or product designs might limit the amount of data available for training without compromising sensitive information. Moreover, stringent regulations can restrict how manufacturers collect, store, and utilize data for AI training, necessitating careful consideration of data anonymization and responsible data management practices.

Explainability and interpretability

The complex algorithms powering generative AI models can be difficult to understand, making it challenging to comprehend the reasoning behind their decisions. When AI recommendations impact critical decisions regarding production or safety, the lack of transparency can hinder trust and acceptance from stakeholders like engineers or production personnel. Further, if an AI system produces unexpected results, it can be difficult to diagnose the root cause without understanding the internal decision-making process. Not to forget, certain regulations in industries like healthcare or automotive might require manufacturers to explain and justify AI-driven decisions. Lack of explainability can pose challenges in adhering to such regulations.

Integration with existing infrastructure

Integrating AI solutions with existing manufacturing infrastructure requires careful planning and execution. Compatibility issues can arise, as existing systems and workflows may not be readily compatible with AI solutions, requiring upgrades or adaptations to hardware, software, and communication protocols. Implementing AI when you hire generative AI developers can also necessitate changes in work processes and employee roles, requiring effective change management strategies to ensure workforce buy-in and successful adoption. Additionally, integrating AI solutions introduces new entry points for potential cyber threats. Robust cybersecurity measures need to be established to safeguard sensitive data and ensure the integrity of AI systems.

Addressing these challenges is crucial for successful AI adoption in manufacturing. Strategies like data collaboration with partners, leveraging synthetic data generation, and investing in explainable AI models can help overcome data availability and interpretability hurdles. Moreover, careful planning, collaboration between teams, and addressing compatibility and security concerns can facilitate the smooth integration of AI solutions with existing infrastructure. By acknowledging and proactively addressing these challenges, manufacturers can truly harness the incredible potential of generative AI.

The Future of Generative AI in Manufacturing

The field of generative AI research is constantly evolving, with exciting advancements holding immense potential to further transform the manufacturing industry. Researchers are actively exploring ways to improve model explainability, enhance data efficiency, and broaden the scope of generative AI applications. This continuous development promises even greater benefits for the manufacturing industry.

For instance, Researchers are actively developing methods to make AI models more interpretable, nurturing trust and transparency in their decision-making processes. Plus, the ability to design and optimize intricate systems with intertwined variables holds immense potential for industries like aerospace and electronics. Lastly, AI models capable of autonomously learning from real-time data and adapting their strategies can revolutionize production line optimization and predictive maintenance.

In conclusion, generative AI presents a transformative vision for the future of manufacturing. By overcoming the existing challenges and leveraging ongoing advancements, manufacturers can utilize this technology to optimize processes, enhance product quality, personalize offerings, and ultimately, shape a more innovative and efficient manufacturing landscape.

Build Your Agile Team

Hire Skilled Developer From Us

Integrate generative AI in your manufacturing processes and stay ahead of the curve

Generative AI can be a game-changer for your manufacturing business and at Webclues, we can help you integrate the technology into your processes. Connect with us to optimize your business efficiency with our comprehensive GenAI solutions.

Get a Quote!Our Recent Blogs

Sharing knowledge helps us grow, stay motivated and stay on-track with frontier technological and design concepts. Developers and business innovators, customers and employees - our events are all about you.

Contact

Information

Whether you're building next door or across time zones, we stay close in ideas, in execution, and in support.

India

Ahmedabad

1007-1010, Signature-1,

S.G.Highway, Makarba,

Ahmedabad, Gujarat - 380051

Rajkot

1308 - The Spire, 150 Feet Ring Rd,

Manharpura 1, Madhapar, Rajkot, Gujarat - 360007

UAE

Dubai

Dubai Silicon Oasis, DDP,

Building A1, Dubai, UAE

USA

Atlanta

6851 Roswell Rd 2nd Floor, Atlanta, GA, USA 30328

New Jersey

513 Baldwin Ave, Jersey City,

NJ 07306, USA

California

4701 Patrick Henry Dr. Building

26 Santa Clara, California 95054

Australia

Queensland

120 Highgate Street, Coopers Plains, Brisbane, Queensland 4108

UK

London

85 Great Portland Street, First

Floor, London, W1W 7LT

Canada

Burlington

5096 South Service Rd,

ON Burlington, L7l 4X4

Let’s Transform Your Idea into Reality. Get in Touch